Test and repair of medical ultrasonic transducers

TRZ® Analyzer and PiezoClamping® applications

Power ultrasonic equipment is expensive, especially those used in medical applications. Repairing ultrasonic transducers and other components can often be economically viable. To perform repairs, qualified professionals, proper procedures and dedicated instrumentation for testing and quality control are necessary.

During the repair of ultrasonic transducers and components, PiezoClamping® contributes by enabling the ideal prestress to be applied during the transducer bolt reassembly. The TRZ® Analyzer, in turn, facilitates the identification of faulty elements, enables testing of piezoelectric ceramics to detect cracks and perform quality control to ensure that the repaired element is within the acceptable frequency, impedance, and mechanical quality factor ranges. The TRZ® Analyzer can test any medical power ultrasonic transducer in the range of 1 to 200 kHz.

Next, some practical application examples of the TRZ® Analyzer and PiezoClamping® in the test and repair of medical ultrasonic transducers.

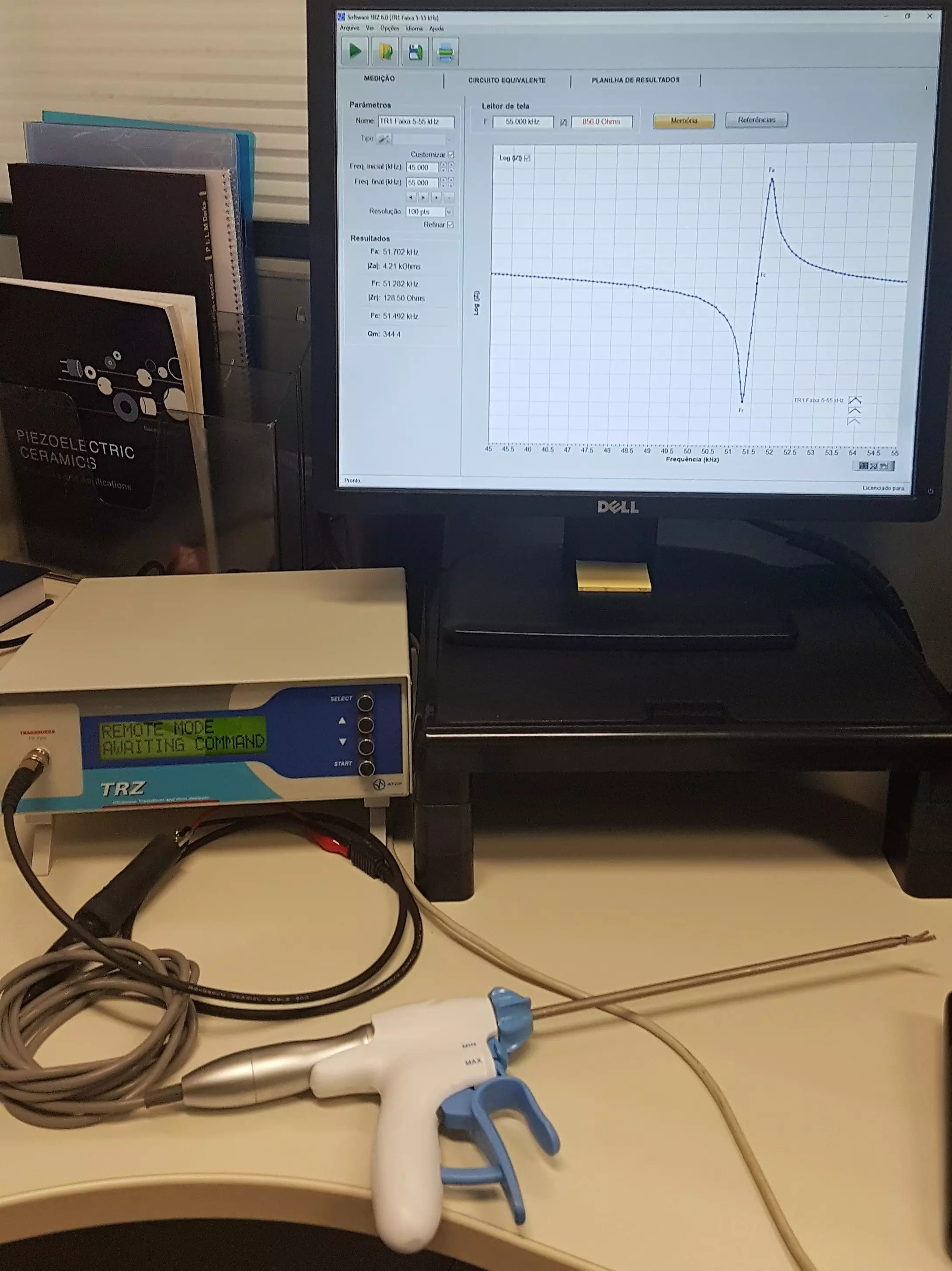

Ultrasonic blood vessel sealing clamp test using the TRZ® Analyzer.

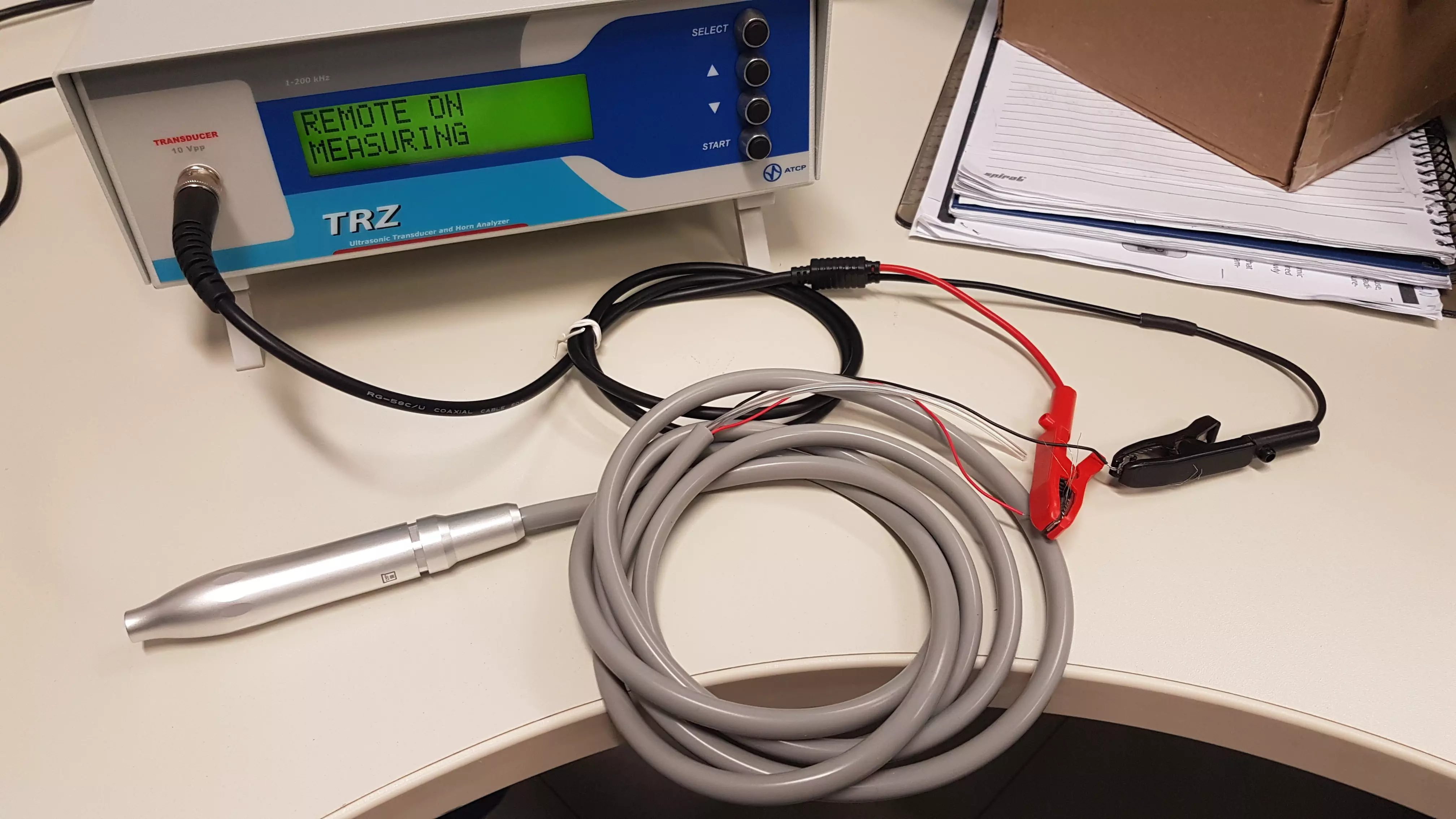

Test of a surgical transducer for cutting bone tissue using the TRZ® Analyzer.

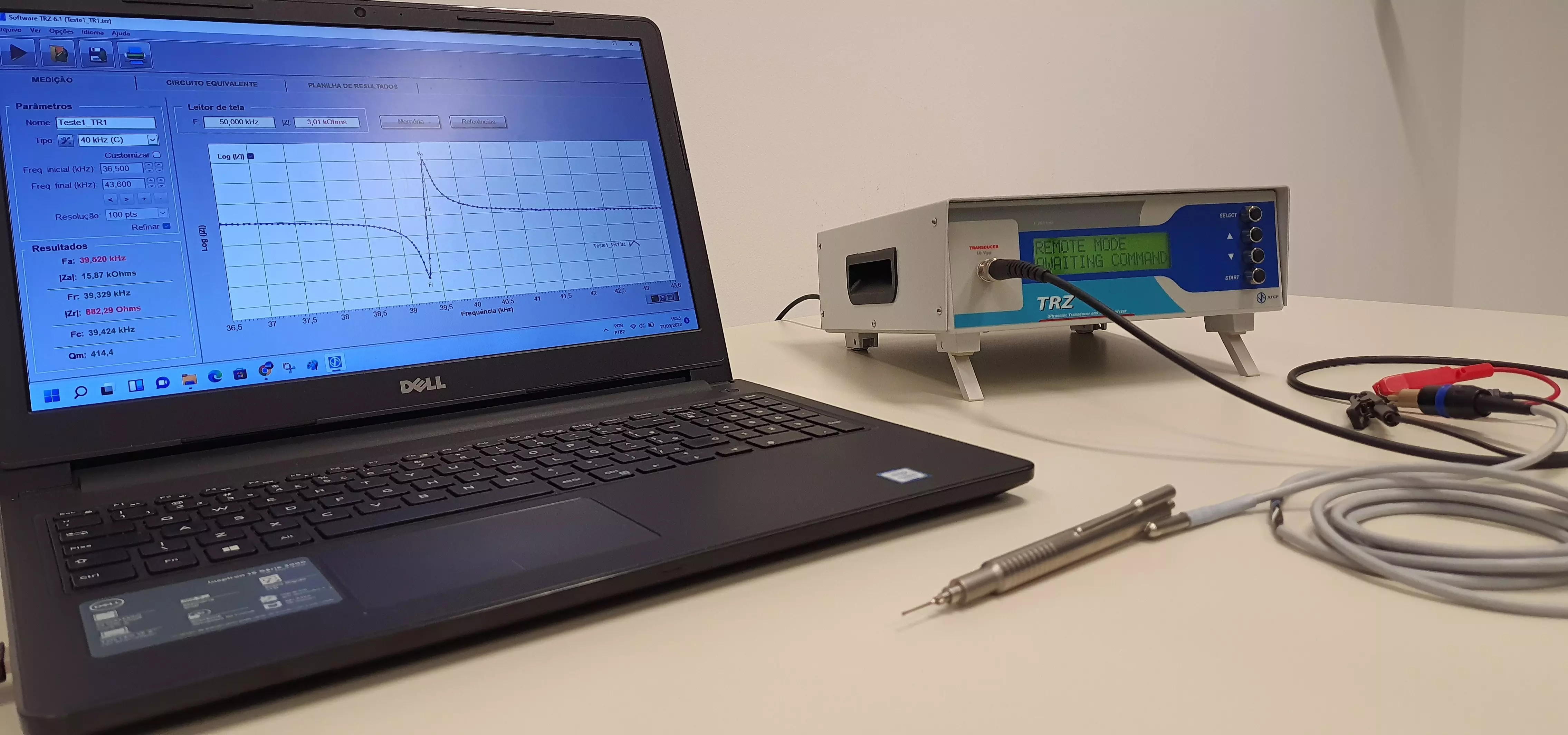

Testing of a phacoemulsification transducer using the TRZ® Analyzer.

Disassembled medical transducer for replacement of defective component.

Ultrasonic lithotripsy transducer being assembled with prestress control by PiezoClamping®.