Soneteste® - Ultrasonic frequencies analyzer

For frequency analysis of ultrasonic devices, monitoring of ultrasonic welding machines, and resonant ultrasonic spectroscopy.Soneteste® Software is dedicated to supervision of ultrasonic welding machines, Frequency analyses of ultrasonic devices and resonant ultrasound spectrometry in accordance with the ASTM E2001 standard. Allows frequency analysis via spectrogram and signal spectrum for a selectable time interval. Apply up to 25 programmable criteria, generate pdf reports, export results to spreadsheet, and can be calibrated Calibratable with SI traceability.

Systems formed by the Soneteste® Software and its accessories can test specimens, test objects, and ultrasonic equipment. Specimens may include rods, rectangular bars, discs, and rings made of raw materials, while test objects encompass various parts, elements, and finished products. Ultrasonic equipment comprises transducers, converters, acoustic transformers, boosters, sonotrodes, ultrasonic horns, ultrasonic tips, ultrasonic cleaners, ultrasonic welding machines, ultrasonic medical equipment, and general power ultrasonic equipment.

Soneteste® Software accessories consist of supports and excitation, capture and signal processing devices (see catalog for more information).

Specifications:

| Parameters | |

| Frequency range: | 20 – 192 kHz |

| Acquisition time: | 0,34 - 5,46 s |

| Number of programable judgement criteria: | 25 |

Soneteste® primary applications include:

- Supervision of ultrasonic welding machines for early deviation detection.

- Determination of the operating frequency of ultrasonic cleaning equipment.

- Basic modal analysis of ultrasonic devices.

- Tuning of ultrasonic horns, sonotrodes, transducers, and acoustic transformers.

- Frequency Analyses and troubleshooting of power ultrasonic generators.

- Inspection of sintered powder parts for cracks and defects.

- Quality control of grinding wheels.

- Detection of defects and internal cracks by resonant ultrasonic spectroscopy (RUS).

- Quality control through acoustic signature.

- Frequency calibration of ultrasonic sources.

Below are some practical examples of how to apply Soneteste®.

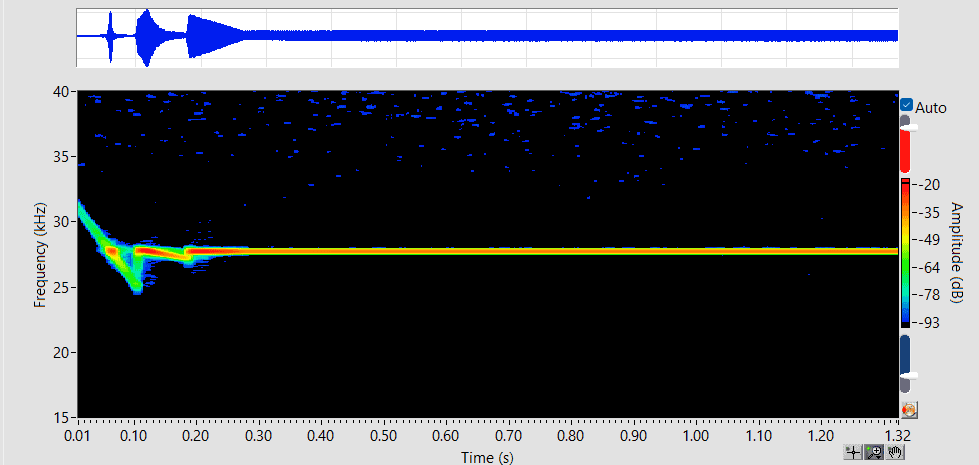

Analysis of the auto-tuning behavior of ultrasonic generators

The Soneteste® Software enables the visualization of ultrasonic generator frequency behavior, making it a valuable tool for the development, improvement, and maintenance of high-power ultrasonic equipment.

In the image above it is possible to observe a sweep from 31 to 25 kHz between 0.00 and 0.10 s, followed by a refinement between 0.10 and 0.20 s. Then, between 0.20 and 0.30 s, the generator performs a linear amplitude adjustment while maintaining a constant frequency.

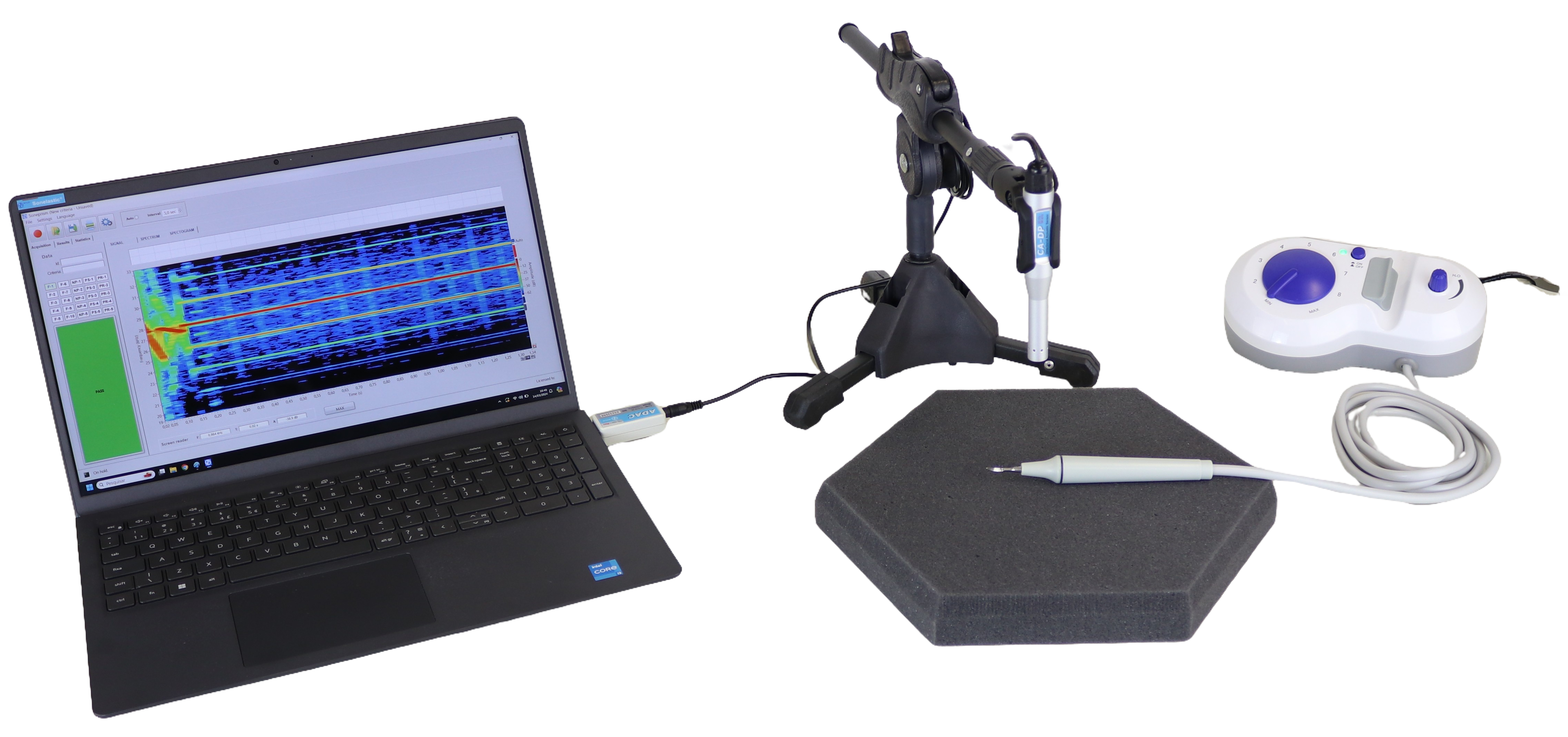

Tuning of ultrasonic welding sonotrodes and boosters

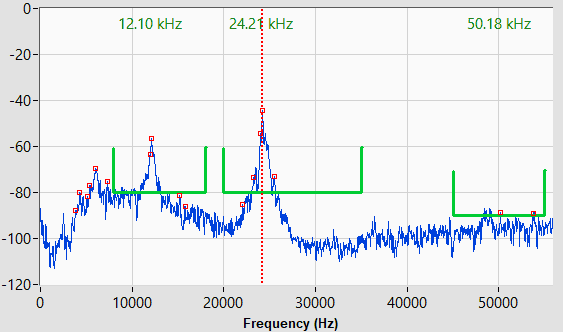

The Soneteste® Software identifies the main frequency and lateral modes without requiring coupling to a converter or performing a basic modal analysis.

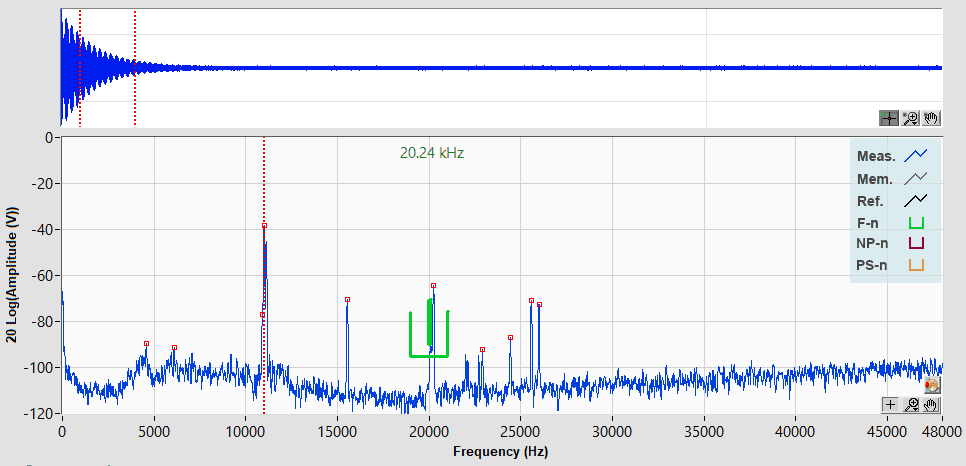

The figures above show the test and the acoustic response and spectrum of a square sonotrode obtained with the Soneteste®. The excitation was applied to the front face. The measured frequency (20.24 kHz) is too high for a 20 kHz sonotrode. The peaks around 11.0 kHz and 15.5 kHz are lateral modes.

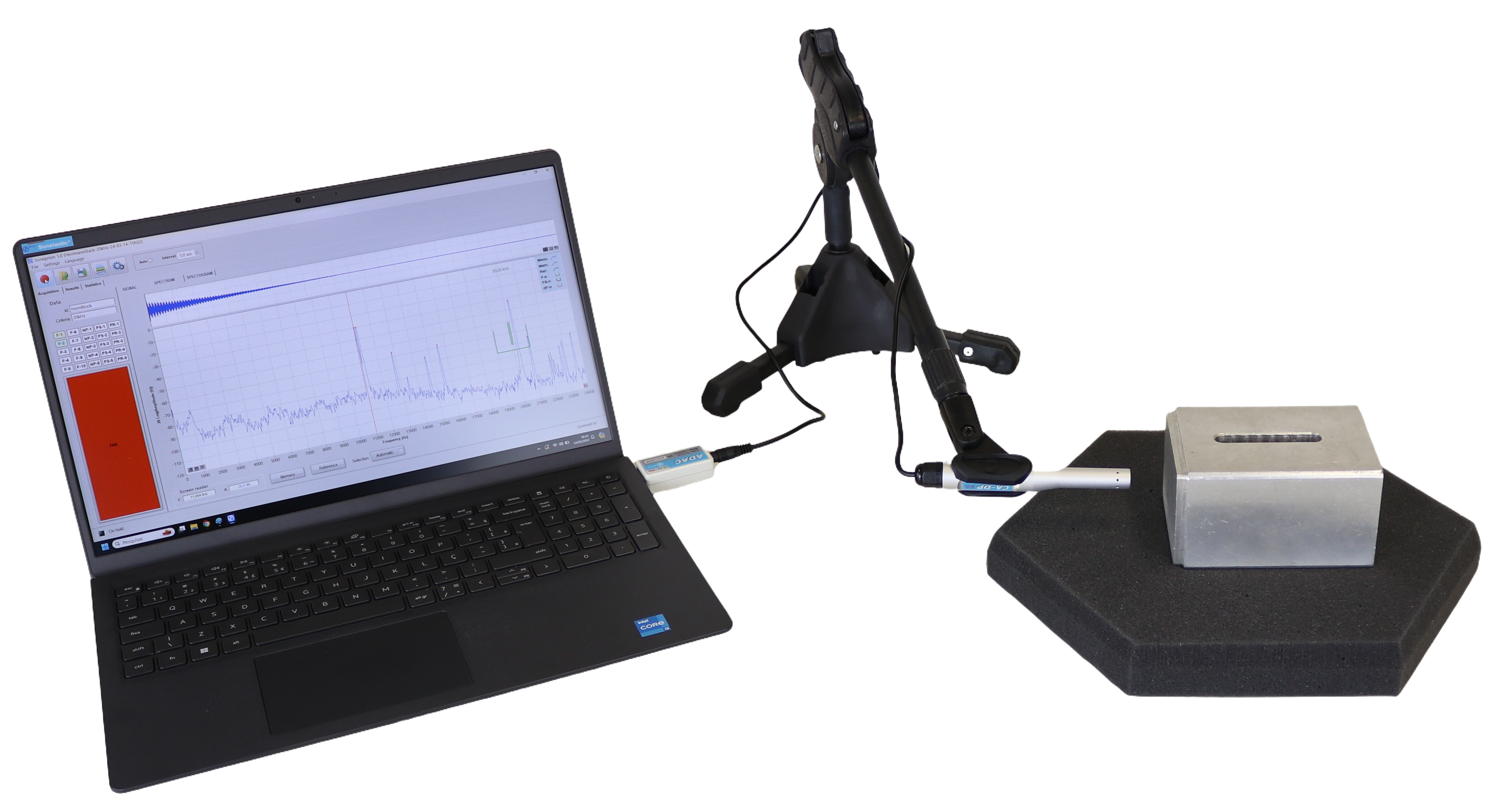

Inspection of grinding wheels and parts by resonant acoustic spectroscopy

The Soneteste® Software enables defect detection through resonant acoustic spectroscopy of metallic and non-metallic parts in accordance with ASTM E2001-18.

The overall evaluation of abrasive wheels for crack detection is based on the detected frequencies and the ratio between these frequencies. It is also possible to use criteria based on the number of frequencies, peak splitting, and peak spacing.

Quality control of hospital and industrial ultrasonic cleaners

The Soneteste® Software complies with ABNT NBR 17130-1:2023 for determining the operating frequency of hospital ultrasonic cleaners.