TRZ® Analyzer - Ultrasonic transducer and horn analyzer

For testing and tuning power ultrasonic transducers, converters, boosters, horns and stacks.TRZ® Analyzer is a dedicated test instrument for the maintenance, manufacturing and quality control of power ultrasonic transducers, converters, boosters, horns and acoustic stacks. The TRZ is for these elements as an oscilloscope is for the electronics. The TRZ allows the ultrasonic parts to become just as testable as any other electrical-mechanic device would be.

The proper frequency, mechanical quality factor and impedance are indispensable for any power ultrasonic equipment and piezoelectric device. The frequency depends mainly on the material’s properties and dimensions, e.g. horn length. The mechanical quality factor and impedance depend mostly on the parts coupling and friction on interfaces. Deviations indicate the need for tuning, reconditioning or replacement.

Important note: The TRZ® Analyzer was developed and is manufactured by ATCP Physical Engineering. We do not have distributors or resellers for this product other than those specified on our contact webpage. TRZ® is a registered trademark owned by ATCP Physical Engineering.

TRZ® Software

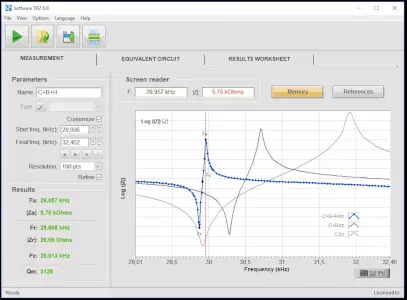

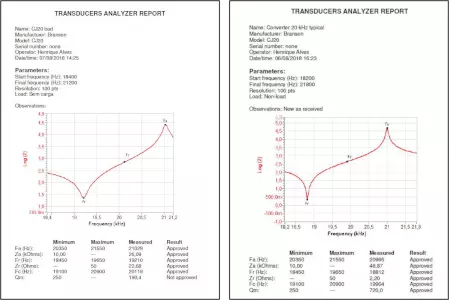

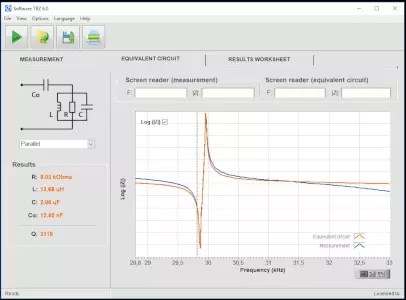

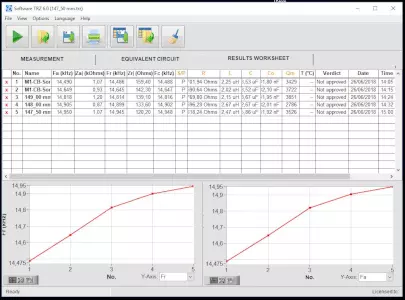

TRZ® Analyzer includes the TRZ® Software, which makes possible to save, recover, compare and graph test results easily. The TRZ®Software also applies acceptance criteria for go/no go testing, generates tests report and determines the BVD equivalent circuit.

Images above (click the pentagons to browse through images) show charts of a 20 kHz converter alone (light gray), 20 kHz converter plus booster (dark gray) and complete stack (blue); results printed in green indicate the stack is in good condition, those printed in red indicate problems; test reports examples in pdf format and the BVD equivalent circuit tab.

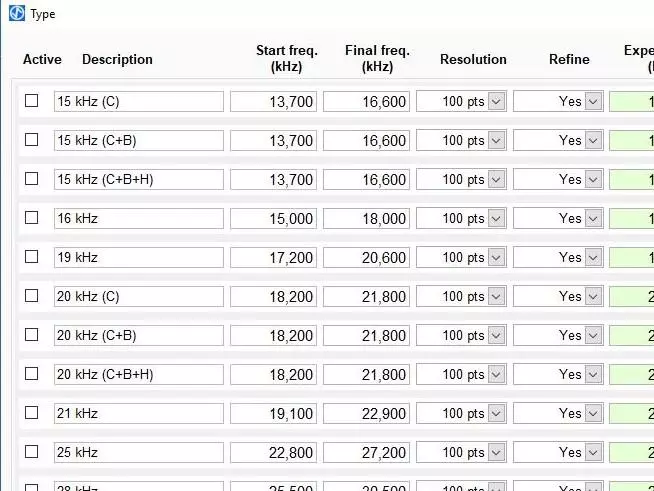

Over the years, we have learned the typical deviations of power ultrasonic falty parts and condensed this knowledge on preprogramed general acceptance criteria for testing converters alone, converters coupled to boosters and complete stacks with regards to frequency, impedance and mechanical quality factor. Those criteria are preprogramed on the TRZ® Software as shown on the figure above. They all can be refined and/or expanded by the user.

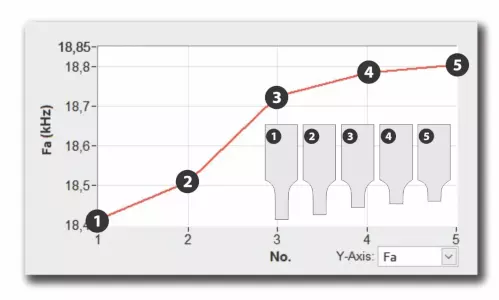

TRZ® Software allows continuous monitoring of frequency and other parameters variation along the machining process of tuning sonotrodes, as well as a function of time and temperature. It is possible to chart, compile and export results to spreadsheet.

Technical specifications:

| Parameter | |

| Frequency range: | 1 - 200 kHz with 1 Hz resolution. |

| Frequency uncertainty (2σ): | ± 0.05 % @ 25 °C. |

| Impedance modulus range: | 0.1 Ω - 999.9 kΩ. |

| Impedance modulus uncertainty (2σ): | ± 3 % @ 20 kHz within the range 0.1 - 10 kΩ. |

| Mechanical quality factor (Q) range: | 1 - 100000. |

| Output voltage: | 10 Vpp maximum. The load may be grounded. |

| BVD equivalent circuit calculation: | Series and parallel. |

| Electrical discharge protection: | 400W peak pulse at 10/1000μs waveform. |

| Operation: | Stand alone and/or with computer. |

| Power supply: | 90-260 VAC 50/60 Hz. |

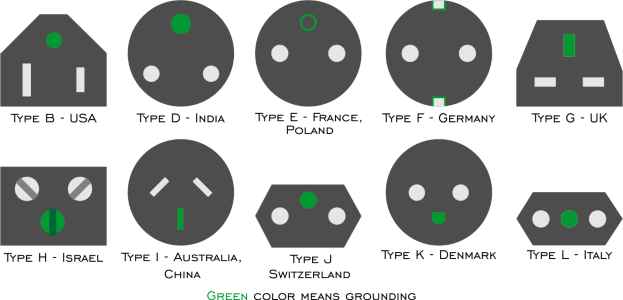

The TRZ® Analyzer is a sturdy and user-friendly test instrument compatible with worldwide power supply voltages and delivered with the most suitable power cord type according to the customer's country standards (types B, E, F, G and J are usually in stock for next day shipping). The TRZ® Analyzer is fitted with electrical discharge protection in case of accidental connection to charged piezoceramics, heavy-duty buttons and rugged metallic enclosure with space-saving footprint.

Every unit is subjected to strict and meticulous quality control and supplied with a 2-year world-wide warranty. ATCP ensures to always keep units in stock for shipping the next day by courier to any country served by UPS, DLH or FedEx.

Industries we serve with TRZ® Analyzer

We are experienced in serving a broad range of industries, as listed below, which include end-users and equipment manufacturers.

- Auto parts manufacturers (maintenance, horn manufacturing and receipt inspection);

- Ultrasonic welder manufacturers (tuning process, quality control and horn development);

- Ultrasonic cleaner manufacturers (tuning process and quality control);

- Medical equipment manufacturers (quality control and receipt inspection);

- Healthcare industry (maintenance, horn manufacturing and receipt inspection);

- Mattress manufacturers (maintenance and receipt inspection);

- Wire dies manufacturers (maintenance and horn manufacturing);

- White line manufacturers (receipt inspection);

- Footwear manufacturers (maintenance and horn manufacturing);

- Underwear manufacturers (maintenance and horn manufacturing);

- Fish finder manufacturers (quality control and underwater transducers development);

- Eyeglass lenses manufacturers (maintenance of cleaning systems);

- Fishing lures manufacturers (maintenance and horn manufacturing);

- Water and energy meters manufacturers (maintenance and horn manufacturing);

- Mining industry (maintenance and ultrasonic cleaning boxes refurbishing);

- Ultrasonic additive industry (maintenance, horn manufacturing and development);

- Research groups (piezoelectric and ultrasonic devices development);

- R&D departments (product development);

- Sensors manufacturers (maintenance, quality control and receipt inspection).

The manufacturers usually buy the TRZ® Analyzer for the development, parts tuning during manufacturing and quality control. The end-users usually buy the TRZ® Analyzer for receipt inspection, maintenance and independent ultrasonic horns manufacturing. We also do have experience in serving R&D departments and research groups. In these cases, the TRZ® Software BVD-equivalent circuit’s tools are especially useful.

Learn more about horn tuning and stack testing with the TRZ® Analyzer