- Details

On July 16, 2025, ATCP Physical Engineering proudly celebrates 25 years of dedication to the development and manufacture of instrumentation for power ultrasound and material characterization. Founded in 2000 as a spin-off from the Federal University of São Carlos (UFSCar) in Brazil, the company was initially established to manufacture piezoelectric ceramics. It quickly shifted its focus to the development of specialized instrumentation, where it has since built a strong reputation across both industrial and scientific sectors. Today, ATCP’s reach spans the globe through an established network of distributors and commercial partners.

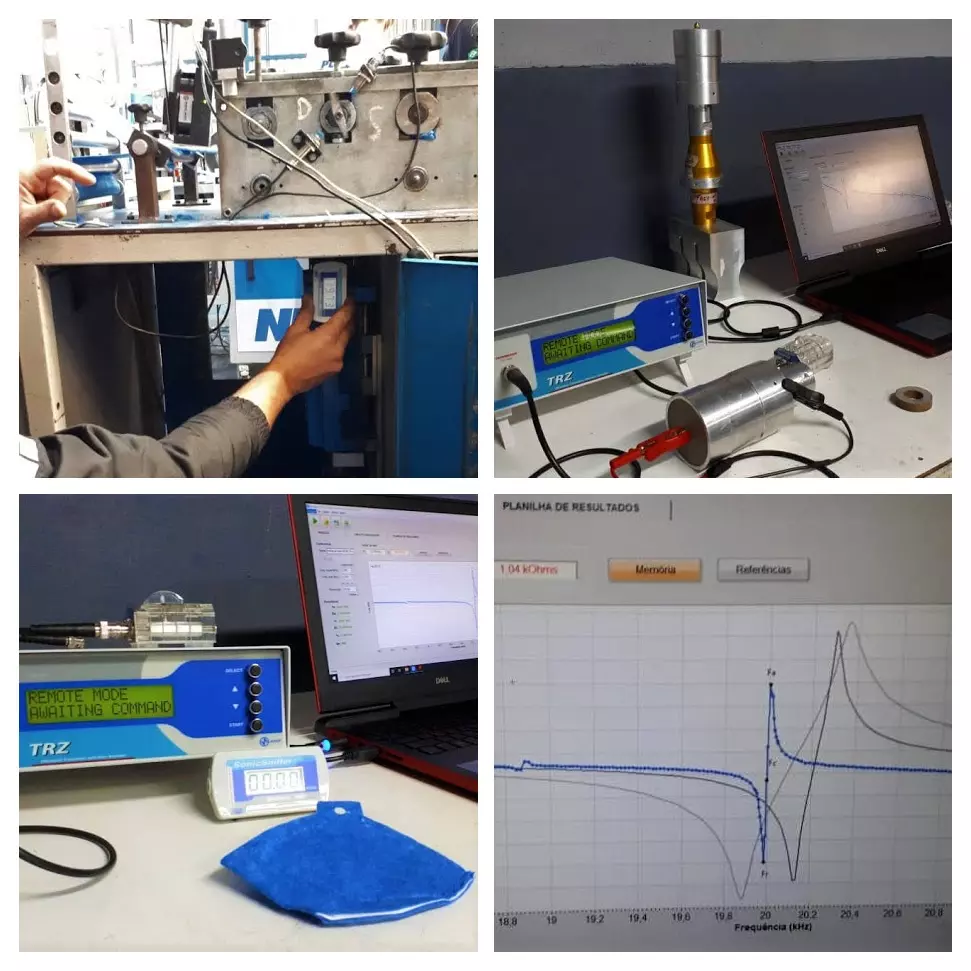

Over the years, ATCP has developed testing instruments that have become benchmarks in industrial, academic, and medical applications. The TRZ Analyzer and SonicSniffer are now essential tools for maintaining and ensuring the quality of power ultrasonic equipment, such as ultrasonic welding machines and medical transducers. The Sonelastic system, developed in collaboration with UFSCar, has advanced the non-destructive testing of elastic moduli in materials such as concrete, composites, and wood.

Another standout innovation is PiezoClamping, a groundbreaking technology that enables real-time measurement of the prestress applied during the assembly of ultrasonic transducers. This innovation enhances both the performance and longevity of the equipment.

ATCP is also recognized for its contributions to technical standardization, actively participating in the development and revision of international and national standards. Notably, the company played a key role in ASTM E1876 and ABNT NBR 8522-2, both of which relate to the characterization of elastic properties in materials and concrete.

During the COVID-19 pandemic, ATCP made a particularly meaningful contribution by supplying instruments and technical training for the production of ultrasonic welding machines used in the manufacture of disposable face masks, a moment that highlighted how its technology could directly support global public health efforts.

Backed by a highly skilled and dedicated team, ATCP continues to pursue its mission of designing, producing, and delivering test and measurement solutions that address critical challenges faced by its customers. Looking to the future, the company reaffirms its commitment to creativity, quality, and integrity, values that have guided its journey from the very beginning. ATCP’s vision for the coming years is clear: to strengthen its position as a global reference in power ultrasonics and materials characterization.

- Details

Disposable face masks are one of the most effective weapons in combating Covid-19. As a result, the world experienced a shortage of this product in 2020, which is manufactured using ultrasonic welding. Mask manufacturers had to expand production and many companies in nearby industries have joined in a global effort to meet the demand surge. ATCP collaborated with this effort by providing training and test instruments for masks manufacturers and ultrasonic welding equipment companies.

- Details

ATCP participated in the development of an experimental system for researches with guided wave for defect detection and location on multilayer tubular structures. The system is capable of generating longitudinal and torsional guided waves, capturing transmitted and reflected signals and analyzing these signals.

ATCP's service consisted in the development of ultrasonic transceivers, instrumentation for field use and software for signal processing.

Link: Consulting and advisory

- Details

ATCP provided elastic moduli characterization services for finite element modeling and analyses refinement. It was characterized tool steels, aluminum and titanium alloys applying the Sonelastic® FEM with only 0.15% uncertainty.

The knowledge of the elastic moduli exact values is crucial for accurate FEM/FEA.

- Details

ATCP provided consulting and consultancy services for the development of an ultrasonic-catalyzed electrochemical incinerator. Ultrasonic by Langevin-type transducers was applied for the dispersion of pathogenic agglomerates, homogenization and cleaning of UV lamps.

The ATCP service consisted in scaling the ultrasound, prospecting the suppliers and following up the ultrasonic equipment tryout and startup.

Link: Consulting and advisory