FAQ: Does the prestress applied decrease over time? May I untighten the converter connected to the PiezoClamping® to evaluate the retained prestress? Applying and removing torque multiple times to the transducer will improve prestress retention?

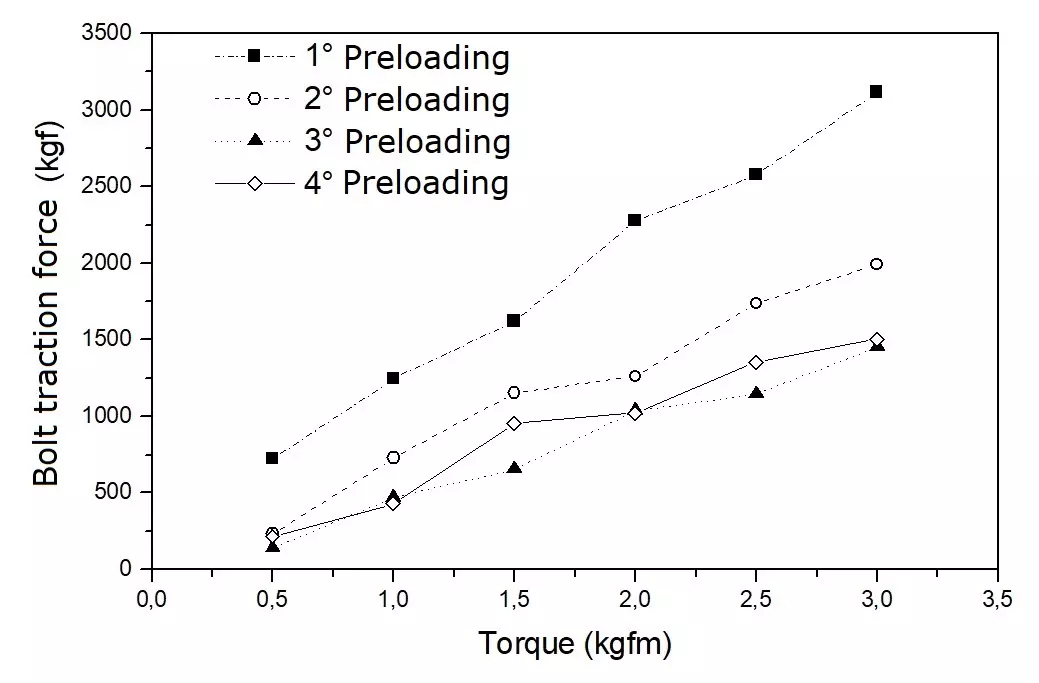

Transducer bolt tensile force as a function of torque and number of preloading cycles.

Relaxation on prestress will always occur, 10-15% is usual for ultrasonic welding converters. More than that indicates you may have a problem with the mechanical design. The prestress will decay exponentially over time until it stabilizes with a few days. If your objective is to determine the retained prestress, you should wait for at least one day. To accelerate the aging process, you can apply low power at the transducer or thermal cycles within the temperature operation range. The vibration and the micro movements caused by the different thermal expansion coefficients will speed up the relaxation process.

To measure the retained prestress, simply unbolt the transducer or converter connected to the PiezoClamping®.

Applying and removing torque multiple times to polish the threads will reduce the relaxation and improve stability. However, to perform this process, you must replace the piezoceramics by a metallic ring with the same dimensions of the piezoceramics to avoid damaging the rings. The application of multiple preloading cycles reduces and stabilizes the coefficient between torque and traction force on the bolt / ceramics due to the threads polishing, as shown in the graph above.

Learn more about prestress technology.