FAQ: Can you give me some tips about horn and booster dimension changes for tuning? Mr. F.D.

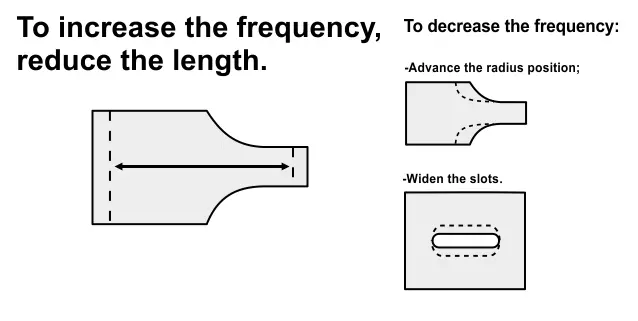

To increase the frequency of ultrasonic horns, reduce the length. To reduce, advance the radius.

The frequency increases if you reduce the part length and decreases if you move the step/radius position or widen slots in steeped horns, as illustrated above. In both cases you need to remove material, however, length changes are straightforward to execute and the frequency sensitivity is much higher. For boosters tuning, the nodal line and clamping region coincidence should also be verified.

Usually, new horns are manufactured with a 3% of length excess (consequently, with low frequency) and then tuned by careful and progressive shortening until they reach the required frequency. The percentage of excess may be lower for series manufacturing. The table below shows the typical frequency sensitivity, length and excess for standard frequencies. These values are for reference only and vary with geometry, aspect ratio and material.

| Frequency | Typical frequency sensitivity for length change | Typical length | Typical excess (≈ 3 % of typ. length) | 15 kHz | 90 Hz/mm (≈ 2 Hz/mil) | 170 mm (≈ 6” 3/4) | 5.0 mm (≈ 200 mil) | 20 kHz | 160 Hz/mm (≈ 4 Hz/mil) | 128 mm (≈ 5”) | 4.0 mm (≈ 160 mil) | 30 kHz | 360 Hz/mm (≈ 9 Hz/mil) | 85 mm (≈ 3” 3/8) | 2.5 mm (≈ 100 mil) | 35 kHz | 480 Hz/mm (≈ 12 Hz/mil) | 73 mm (≈ 2” 7/8) | 2.2 mm (≈ 85 mil) | 40 kHz | 630 Hz/mm (≈ 16 Hz/mil) | 64 mm (≈ 2” 1/2) | 2.0 mm (≈ 80 mil) | |

Notes:

- Wear and surface reworking reduce the horn length causing the frequency to increase, and often, placing it outside the tolerance range. It is possible to recover the horn and reduce its frequency to some extent by widening the slots and advancing the step/radius position of the horn.

- Length change affects the frequency because the ultrasonic part resonates at multiples of half wave-length. When one reduces the part length, they also reduce the half wave-length, increasing the resonance frequency. Frequency and length are inversely proportional.

- Temperature variations affect the material’s speed of sound, consequently the frequency.

- One should be cautious when tuning boosters and converters because of the nodal line. In these cases, besides ensuring the right frequency, it is also necessary to ensure the nodal line and clamping region matching.

FAQ: I tested one of your advice for tuning the frequency, but it doesn't seem to be working. The center frequency of my acoustic set (Converter + Booster + Sonotrode) was 20.20 kHz and I advanced the radius by 1 mm. The center frequency increased to 20.23 kHz, but I expected a decrease. What happened? Mr. F.D.

The procedure you described is correct, the frequency should have decreased instead of increasing, unless other changes also occurred, such as surface polishing or applying higher mounting torque. Since the frequency sensitivity to side dimensions changes is low (1-10 Hz/mm), a possible explanation would be the overlap of a frequency increase caused by a higher effective contact area. Coupling improves with polishing and mounting torque and causes increase in frequency.

Learn more about tuning of ultrasonic horns and testing of acoustic stacks.